Trolley Rail & Short Rail Systems for STS Cranes

Precision-engineered rail solutions for ship-to-shore cranes, designed to ensure smooth trolley rail operation and long-term reliability.

What Are Trolley Rail and Short Rail?

Trolley rails form the running track on STS crane booms and girders, enabling the trolley to move back and forth during container handling. Short rails are specialized connections at the boom hinge joint, bridging the boom rail with the girder rail while allowing the crane to boom up. Engineered for strength and durability, these rails reduce shock, vibration, and wear, ensuring smooth crane operation.

Professional Design & Precision Manufacturing

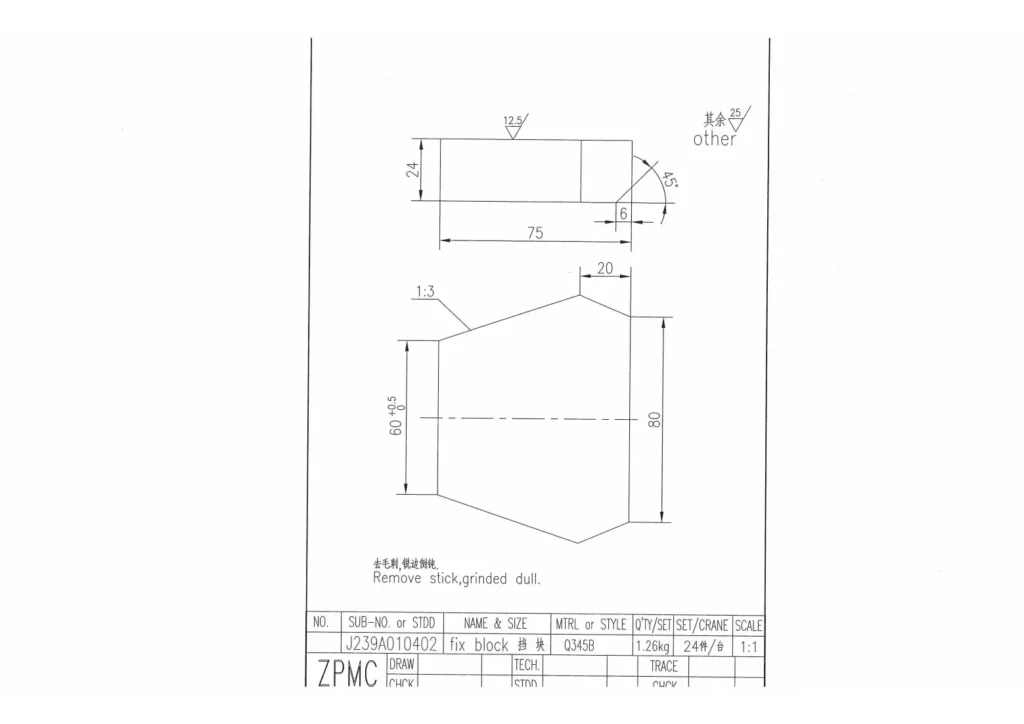

Every detail of our trolley rail system is engineered for excellence, adhering to international standards and benefiting from collaborations with global leaders in heavy equipment manufacturing. The design drawings below, utilized in real-world projects, showcase the precision, material selection, and structural integrity that define our products.

Technical Specifications

| Item | Details | Notes |

|---|---|---|

| Product Name | Fixed Stop Block (Fix Block) | |

| Product Code | J239A010402 | |

| Material | Q345B Low-Alloy High-Strength Structural Steel | High strength, good weather resistance |

| Unit Weight | 1.26 kg | |

| Manufacturing Standard | Complies with ZPMC Technical Specifications |

These drawings are a testament to the superior quality and customizable capabilities of our products. We understand the critical role a reliable trolley system plays in your project’s success.

Contact us today to request the full technical drawing package, customized solutions, and a quote. Our engineering team is ready to support you.

Key Features of Trolley Rail Systems

- High-Grade Steel Profiles – Typically manufactured in A75 or A100 profiles using alloy steels such as 42CrMo4 for maximum strength and durability.

- Secure Installation – Rails mounted on resilient pads and attached with clips, clamps, or bolts for stable alignment.

- Shock-Resistant Short Rails – Reinforced design at boom hinge joints to withstand impacts as the trolley passes between boom and girder.

- Custom Machining – Precision machining available to match specific crane designs and operational requirements.

Materials for Trolley Rails & Short Rails

Our trolley rails are typically produced in A75 and A100 profiles, using high-grade alloy steels such as 42CrMo4 to deliver superior wear resistance and strength.

All materials undergo strict heat treatment, chemical analysis, and hardness testing to ensure stability under heavy crane loads.

By combining premium steel with precision machining, we guarantee long service life, reduced vibration, and consistent performance in demanding port environments.

Tailored Short Rail Solutions

Reinforced Wide-Type Short Rails – Designed for single-box girder crane systems, offering maximum durability.

Standard-Type Short Rails – Optimized for dual-box girder cranes with proven stability.

Flexible Installation Options – Fixed with bolts, clamping plates, or fully welded ends to suit project needs.

Patented Vibration Reduction – Our design improves operator comfort and reduces mechanical wear by minimizing vibration transfer.

Customized Short Rail Processing & Finished Products

From precision cutting and drilling to coating and packing, we showcase the complete short rail production process and finished products.

Every short rail can be fully customized according to your project requirements—ensuring the perfect fit for your application.

Why Partner with Glory Rail?

- Proven expertise in supplying trolley rails and short rails for global STS crane manufacturers.

- Custom design and machining tailored to budget and operational constraints.

- Reliable quality control with ultrasonic testing and factory certification.

- Global logistics support ensuring timely delivery and safe packaging.

Get Your Trolley Rail Solution

We provide custom-engineered solutions that enhance crane performance and operator safety, while minimizing downtime and maintenance costs.

Contact us today to get a tailored trolley rail solution designed for long-lasting efficiency.