Crane Runway Beam

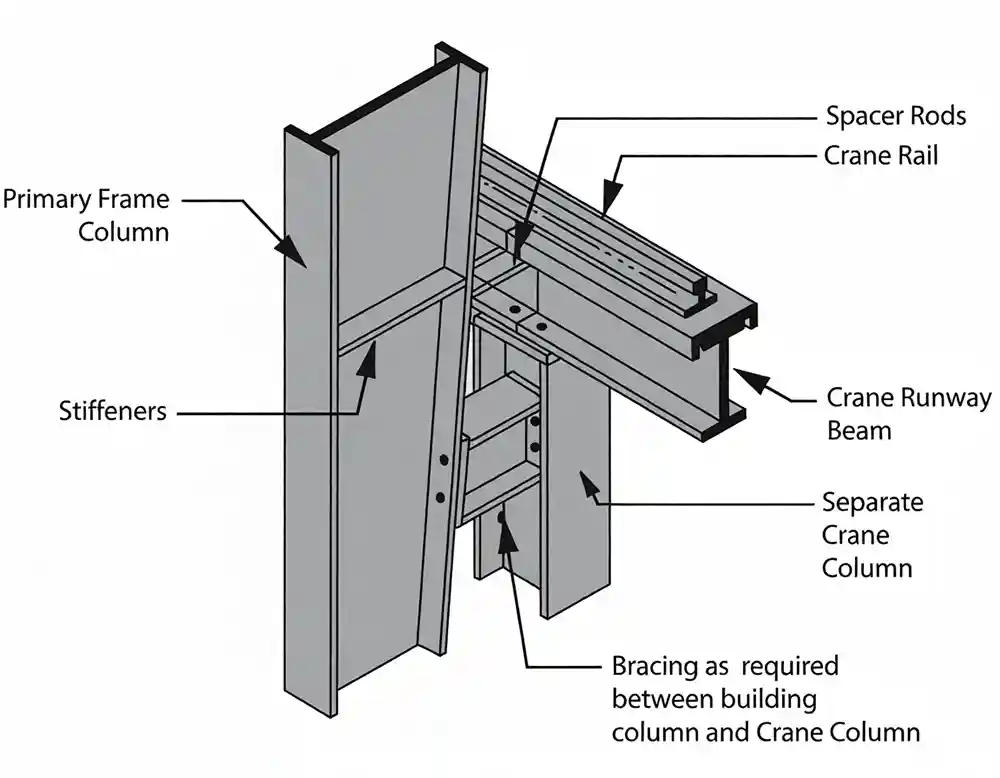

Crane runway beam support overhead, gantry, and suspended cranes. They carry crane weight, lifting loads, and dynamic forces during travel.The building’s structure or other independent supports bear the brunt of these stresses.

The choice of runway beam affects service life, running stability, and permissible load. I-beam and H-beam sections are frequently utilized in the majority of ordinary crane systems because of their accessibility, affordability, and dependable structural performance.

Box girders and other specially designed sections are used for large weights, extended spans, or restricted headroom.

I-Beam Crane Runway Beam

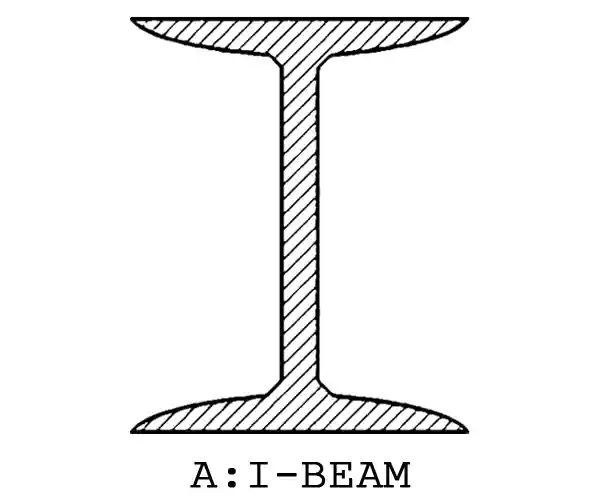

I-beam sections (also known as Universal Beams, UB) are a traditional solution for crane runway beams. The cross-section features tapered flanges and a relatively deep web, produced by hot rolling in a single process. Due to stable supply and controlled cost, I-beams are commonly used in light to medium-duty crane systems.

Key Features

Section design: Narrow flanges with taper. Material is concentrated in the web and flange root, providing good vertical bending resistance.

Mechanical performance: Typical yield strength ranges from 258–345 MPa (Q235B, ASTM A36). Axial and compressive strength are adequate, but lateral stiffness and torsional resistance are limited. Additional lateral bracing is often required for longer spans.

Manufacturing and cost: Hot-rolled production without complex welding. Short lead time and approximately 15–20% lower cost compared with H-beams.

Size range: Section depth from 100 to 630 mm, suitable for crane wheel loads up to 200 kN.

Typical Applications

Overhead cranes with rated capacity below 50 tons and span under 12 m

Low-duty service classes (U0–U4) and light loading conditions (Q1–Q2)

Warehouses, small workshops, temporary crane installations, or budget-limited retrofit projects

H-Beam Crane Runway Beam

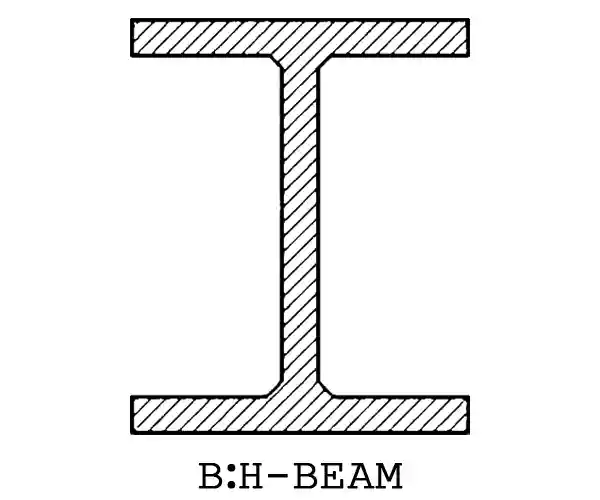

H-beams (Wide Flange Beams, W-beams) are the preferred choice for heavy-duty and long-span crane runway systems. The section has wide, parallel flanges with uniform thickness and a symmetrical shape. H-beams can be hot-rolled or fabricated by welding for non-standard dimensions.

Key Features

Section design: Wide, parallel flanges. Higher moment of inertia than I-beams.

Mechanical performance: Q355B / ASTM A992. Yield strength 345–550 MPa. High torsional stiffness.

Manufacturing: Hot-rolled or welded. Welded sections allow custom sizing.

Size range: 100–1000 mm depth. Wheel loads 200–1000 kN. Long-span capability.

Typical Applications

Medium to heavy-duty cranes (50–200 tons) in steel mills, shipyards, and ports

High-duty service classes (U5–U9) with frequent load cycles and impact loading

Low-headroom workshops, suspended crane systems, and independent outdoor crane structures

I-Beam Steel VS H-Beam Steel

| Comparison Dimension | I-Beam (I-Section Steel) | H-Beam (H-Section Steel) |

| Section Shape | Narrow “I” shape, flanges with 14% taper | Wide “H” shape, parallel and equal-thickness flanges |

| Core Mechanical Properties | Excellent vertical bending resistance, weak lateral stiffness and torsion resistance | Excellent overall performance in bending, torsion, shear resistance and stability |

| Applicable Load | < 50 tons | 50 – 200 tons + |

| Applicable Span | < 12m (max 100 feet) | 12 – 100m (max 330 feet) |

| Production Process | One-time hot rolling, simple process | Hot rolling/welding, customizable non-standard |

| Material Utilization Rate | Medium (conventional level) | High (saves 10%-15% steel compared to I-beam) |

| Core Application Scenarios | Light cranes, small-medium spans, budget-limited projects | Heavy cranes, large spans, high-frequency operation projects |

| Lateral Support Requirement | Necessary (dense supports for large spans) | Optional (only a few supports for large spans) |

Special Runway Beam Options for Non-Standard Applications

| Runway Beam Type | Structural Features | Load & Span Capability | Typical Applications |

| Box Girder Runway Beam | Closed hollow section, welded plates | Ultra-heavy loads, very long spans, high torsional stiffness | Cranes >200 t, spans >30 m, ports, shipyards, nuclear and hydropower facilities |

| Channel Beam Runway Beam | Open C-section, lightweight | Light loads (<5 t), short spans | Suspended cranes, small hoists, low-headroom workshops, warehouses |

| Tee Beam Runway Beam | T-shaped section, flat rail seat | One-directional loading, light to medium loads | Precision handling, automated lines, single-sided loading conditions |

| Composite Runway Beam | Combined steel sections, custom design | Adjustable by design | Non-standard cranes, retrofit projects, special building structures |

Need Help Selecting the Right Runway Beam?

Tell us your crane capacity, span, and working conditions.

Our engineers will recommend the most suitable runway beam solution for your project.