With the continuous development of ports, there is an urgent need for various mechanical products to be applied, as their use can significantly reduce labor, material, and financial resources, thereby promoting rapid growth in the port economy. It can be said that port machinery products play a vital role in the practical development of ports. The increasing utilization and frequency of Ship-to-Shore (STS) cranes accelerate the damage to the crane’s trolley rails. Short rail damage increases noise and impact vibration and, in severe cases, can cause work stoppages. The damage and defect forms of the short rails on STS crane trolley tracks can be summarized as follows:

Introduction to Short Rails

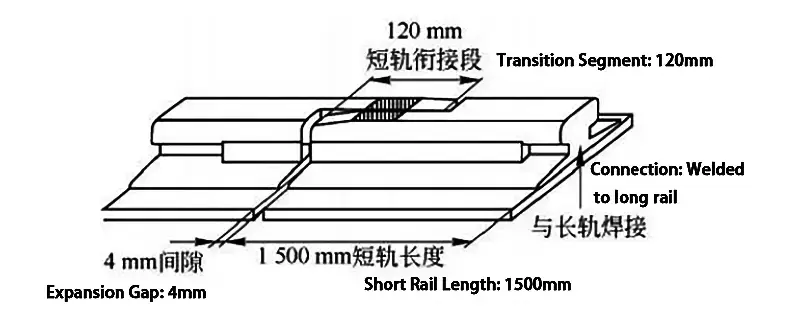

The weakest part of the rail beam is at the hinge point connecting the front and rear girders. Short rails are used precisely at these hinge points, installed in pairs. They connect to the standard long rails on either side. Short rails are specially designed to withstand significant impact. Due to the short rail joint, deformation of the rail beam and the rail itself causes vibration and impact on the rail when the trolley passes over this area.

Early short rails used fishplate connections with the long rails. Because this type of connection is prone to wear and causes bumpiness, it has largely been replaced by welded connections.

The form of the short rail depends on the trolley operation mode. Trolley operation modes mainly include three types: single-box girder heavy-duty self-propelled, double-box girder towed, and double-box girder self-propelled. Accordingly, there are two main forms of short rails: one is a reinforced and widened type matching A120 rail, used primarily on STS cranes with single-box girder heavy-duty self-propelled trolleys; the other is a standard type matching A75~A100 rail, used on double-box girder STS cranes. Classified by fixing method, short rails can be: bolted fixed type, clamp plate (multi-hole, specifically long clamp plate) fixed type, and welded fixed type. The welded short rail fixation method is less common on STS cranes, as manufacturers have differing opinions, but it is more frequently used on yard cranes and rail-mounted gantry cranes.

Short Rail Damage Forms

2.1 Fracture at the Short Rail Positioning Block Location

This is a common form of damage. The design incorporates positioning blocks, requiring notches to be cut into the rail, which reduces strength at these points. Additionally, residual stress from the manufacturing process contributes to fractures here.

2.2 Cracking at the Short-Long Rail Joint

Described instances involve reinforced short rails for heavy-duty self-propelled trolleys. Besides structural factors, poor welding quality is a primary cause of this cracking.

2.3 Edge Spalling/Chipping

Occurs with bolted short rails. Notches from metal spalling appear along the upper outer edge. If unaddressed, this can damage trolley wheel surfaces and guide wheel treads. Analysis shows the main cause is poor trolley tracking (straightness), leading to guide wheels persistently the rail edge. Eccentric bushings on trolley wheels are commonly used to adjust tracking.

2.4 Longitudinal Cracking

Long, multi-layer cracks develop along the length of the short rail. Continued use leads to crack propagation, and spalled metal can damage wheels. Immediate replacement is needed. This is typical brittle fracture, initiated by micro-cracks/defects under stress below yield strength. The high-Chromium alloy steel used is susceptible to temper embrittlement if heat treatment (quenching & tempering) is improper, reducing grain boundary strength and promoting crack growth. Mitigation involves improving heat treatment processes or material selection to reduce temper embrittlement risk.

2.5 Spalling/Cracking at the Short Rail Joint (between paired short rails)

Transverse cracking occurs precisely at the joint between the front and rear short rail pair, exhibiting ductile (plastic) fracture characteristics. The mechanism relates to material properties and microstructure, similar to longitudinal brittle fracture, but under different conditions. Control through material selection and heat treatment is also key.

2.6 Butt Weld Failure

Fracture occurs at the weld joining the short and long rail, matching the weld width. Often happens after re-welding a previously cracked rail. Causes include failure to follow correct welding procedures and use of electrodes with poor impact toughness.

Short Rail Defect Forms

3.1 Butt Weld Defects

(1) Improper welding techniques causing concave defects or pits at the weld, leading to trolley vibration, wheel damage, and rail cracking.

(2) Misalignment during welding causing joint distortion, also resulting in vibration, swaying, accelerated wear. Solutions include advanced techniques like resistance welding (for ground fabrication) and strict adherence to proper manual arc welding procedures for maintenance (including preheat, stress relief, anti-deformation methods).

3.2 Rail Installation/Alignment Defects

(1) Damage/spalling at the hinge joint between the front and rear short rail pair, often due to incorrect maintenance of the specified gap (e.g., 4mm).

(2) Rail baseplate cracking/spalling or full-thickness cracks, sometimes directly caused by improper shimming under the rail.

3.3 Trolley Wheel Installation Defects

Periodic slip marks on the rail indicate a wheel misalignment issue. If one trolley wheel’s end plane is significantly non-parallel to the rail, it gets forced to slip back into position each revolution by the other three wheels, creating scuff marks. This causes noise, accelerates wear on both rail and wheel.

Conclusion

In summary, the forms of damage and defects in STS crane short rails are now quite clear. Short rail failures manifest issues related to manufacturing processes, on-site welding, and ongoing maintenance. Strengthening factory inspections, reasonably avoiding and preventing short rail damage, and reducing defects will enhance equipment operational efficiency for end-users, yielding greater economic benefits.

For professional solutions to short rail damage, including expert manufacturing, repair, and maintenance guidance, welcome to contact Glory Rail.